Although plastics have been around for about 100 years, they have become a significant part of our lives. Plastic recycling is crucial to help us deal with the existing waste and reduce the cost of production. There are social, economic, and environmental consequences associated with our disposal habits. Plastic disposal affects aquaculture, fisheries, recreational activities, and global wellbeing. Ergo, recycling plastic waste is a necessity today.

Common Recycled Plastics

There are numerous types of plastics, and it is essential to familiarize yourself with them before recycling. Luckily, most plastics are recyclable. Here are the common types:

- Polyethylene Terephthalate (PETE or PET) – resin is the main product used in the manufacture of PET. Some examples of PET include plastic bottles for soft drinks or water and food containers.

- High-Density Polyethylene (HDPE) – this type of plastic more flexible and softer. It is used to make gallons and pipes.

- Polyvinyl Chloride (PVC) – is a popular thermoplastic used to produce bottles, pipes, wires, and cling films.

- Low-Density Polyethylene (LDPE) – unlike HDPE, LDPE is highly resilient. Hence, it is used to manufacture products like plastic trash bags, containers, and playground fixtures. It is essential to understand that LDPE is recyclable, but most products are excluded because they pose the risk of clogging the machines.

- Polystyrene (PS) – used in packaging materials and disposable plastic containers for food.

- Polypropylene (PP) – this type of plastic can be used to manufacture clothing, bottle caps, and surgical tools.

Plastic Recycling Steps

- Plastic Waste Collection

The first step entails collecting waste plastic products from homes, institutions, and businesses. Individual waste pickers, private companies, governments, or volunteers can do the collection. It is easier to have a communal collection center with designated facilities or recycling bins to ease collection. However, in most cases, recyclers place recycling bins around residential areas, industrial zones, and offices to ease collection and distribution. At this stage, recyclers retrieve all plastic types and send them to the collecting yard.

- Sorting and separating out

Since there different types of plastics, recyclers sort them out to determine the ones that can be recycled according to type (PET, PP, PS, HDPE, PVC, etc. ) and shapes (packing bags, bottles, containers, etc.). Sorting and categorizing plastics is done by machines to increase efficiency and avoid contaminating the end product. Other properties like thickness, color, and plastic use can be used in sorting and categorizing. However, recyclers usually rely on resin content and color to sort plastics.

- Shredding

Recycling plastic in its developed state is impossible. Therefore, recyclers put the sorted plastic dirties and the impurities into a shredding machine to crush them into small fragments. The plastic is broken down into small pieces (scraps or flakes) by a shredding machine to ease subsequent recycling stages. These small pieces can also be used in other applications, such as additives within asphalt, or sold to manufacturers as raw materials. Breaking down plastics into tiny fragments is essential to find remaining impurities. For instance, if contaminants like metal were not washed away, they can be removed with a magnet at this stage.

- Washing

Washing is an essential step in recycling plastics because it removes impurities. The shredded plastic scraps or flakes material is washed with a plastic recycling washing line to remove all the impurities like product labels, dirt, food residue, and adhesives. Remember, if these impurities are not removed, they can hinder the recycling process or ruin the end product, which affects the quality of the recycled pellets. As a result, it will decrease recycled pellets selling price and lower your profit.

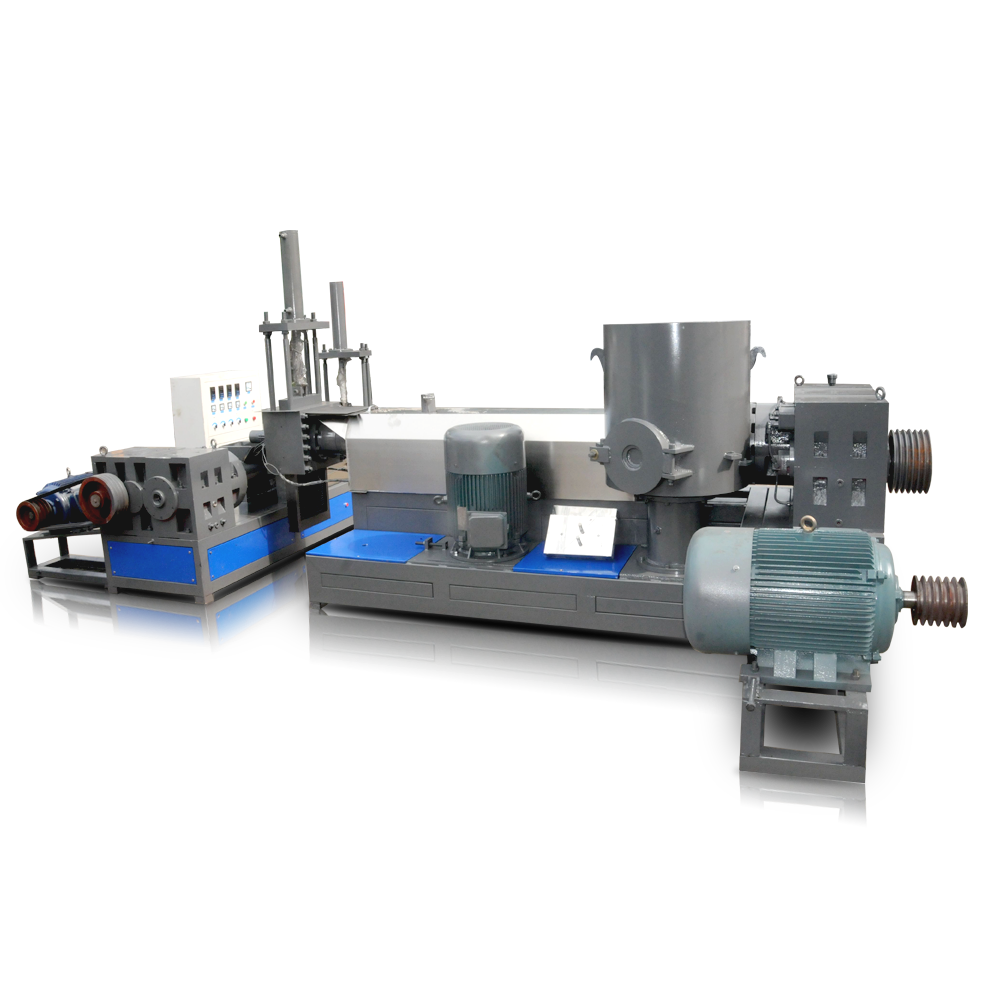

- Extrusion and Pelletizing

The final recycling process is called extrusion and pelletizing. Here, a plastic granulator machine is used to breakdown the washed plastic flakes. The final shape is the pellet. At this stage, a Plastic Granulator Production Line transforms the small fragments into pellets materials manufacturers can use. The process entails smashing, melting, extruding, cooling, and cutting the shredded plastic pieces to form pellets. Pelletizing is the process of obtaining pellets from small plastic fragments. Sometimes, a recycling plant may move the plastic areas for extrusion if they lack workforce or state-of-the-art equipment to process the different plastic types identified. Extrusion is time and energy-consuming because recyclers must know the process and the end product they want.

Identification and Test

After the pelletizing process, the recycled pellets will be used to manufacture new plastic products. In identification and separation, several testing procedures are used to identify and test the recycled plastic pellet’s quality. This stage’s main objective is to determine the class and quality of the plastic to be recycled. Several features are tested:

- Density – the plastic particles are placed in a water container to determine their density. The less-dense plastic pieces sink, but denser plastic pieces float.

- Air classification – air classification is used to determine the thickness. The plastic pieces are put in a wind tunnel. The thinner plastic pieces float while thicker and bigger pieces remain at the bottom.

- Melting point and color – the color and melting point determined to separate the plastic pieces and continue with the recycling process.

Challenges Facing Plastic Recycling

Some of the challenges facing the recycling industry include:

- Mixed plastics – since there are different types of manufactured plastic, it is challenging for recyclers to sort them in their recycling plants. Remember, it is difficult for consumers to dispose of plastics properly, let alone sorting them when disposing of them! Sorting mixed plastics consumes a lot of time, but it is essential to increase efficiency and the end product’s quality.

- Hard to remove residues – thorough washing is done to remove impurities. However, some residues are hard to remove, making the entire recycling process daunting. Remember, these residues/contaminants must be removed to avoid affecting the quality of the end product. Sometimes, removing adhesives or labels may consume a lot of time, making the process cumbersome.

- Recovery and collecting recycling plastics – typically, local authorities and recovery facilities do not recover and collect recycling plastics due to the lack of manpower, equipment, or funding. If the governments play their role, environmental pollution can be reduced as more plastics would be collected for recycling.

What are some of the benefits of plastic recycling?

- Creating new jobs. Develop recycling economy. Plastic waste is money.

- Preventing global warming

- Protect our environment, decrease pollution. (Plastic can not be decomposed)

- Reducing the amount of trash ending up in oceans and other water bodies

- Creating additional revenue to private organizations and government

- Reduce the release of carbon dioxide and other harmful gases into the environment.

- …

Lots of benefit in recycling plastic, it will be a broad market and development prospects. Plastics are vital in our daily lives. However, with plastic recycling and advanced technology, the government and learning institutions need to weigh in and educate the public on proper plastic disposal to reduce pollution and ease the recycling process. Believe many enterprises are engaging in recycling technology. Enviro Machinery dedicates to improve our Plastic Recycling Pelletizing Machine Production Line to assist our client’s plastic recycling business.