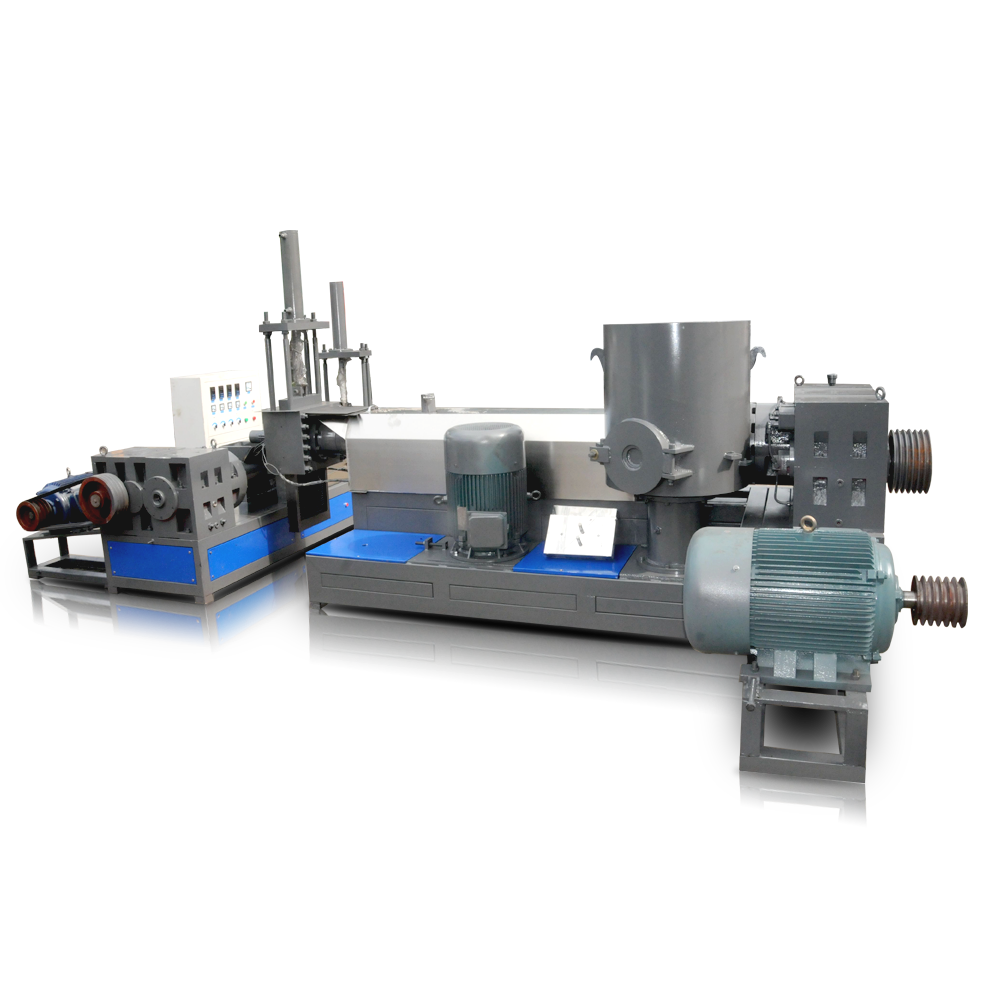

With more and more concern about the recycling economy, the plastics recycling industry is a sunrise industry in the 21st century. Now more and more choose to run recycle plastic business through plastic recycling granulators turning waste plastic particles into renewable recycled plastic pellets which can be reused to produce new plastic products.

Many people do not know how to choose a good performance PLASTIC RECYCLING PELLETIZING MACHINE. Some clients just directly ask: how much a plastic granulation production line? It is difficult to buy a suitable plastic granules-making machine. Today Enviro Machinery(Trump Machinery) engineers tell you how to choose a great set of plastic recycling granulator equipment.

- Identifying the shapes of plastic waste shape is important. Waste plastic, if they are sorted, shredded/crushed, washed?

- And what are the types, LDPE, HDPE, PS, PP, PVC, PET, Nylon, etc?

- What’s more, how much output you expect?

Before you inquiry a plastic recycling machine, please confirm the above three questions.

There are many kinds of waste plastics, which can be divided into post-industrial plastics and post-consumer plastics according. Post-consumer plastics are with large output, low price, and wide application range, PE, PP, and PVC polyvinyl chloride, PS (polystyrene), and Amino plastic five varieties. Many products are used in people’s daily life such as PE film, PP woven bags, PVC plastic pipes, and these are made of general-purpose plastic. Post-industrial plastics can be used as engineering structural materials and they can be suitable to make machines and Auto plastic parts, hard plastic products, etc. For example, industrial plastics mainly include polycarbonate, PC, polyamide nylon PA, Polyformaldehyde, POM, polyphenylene oxide PPO, polyester PET, PBT, poly(p-phenylene sulfide), and so on. When we choose the plastic recycling granulator production line, it is best to choose according to the shape and material types of plastic, such as film, woven bags, and other soft plastics; ABS, HDPE, and other hollow broke hard materials so that the particles are produced with high purity recycled pellets and sold at a good price. The output capacity depends on your investing budget, plastic recycling plant size, and the number of workers.