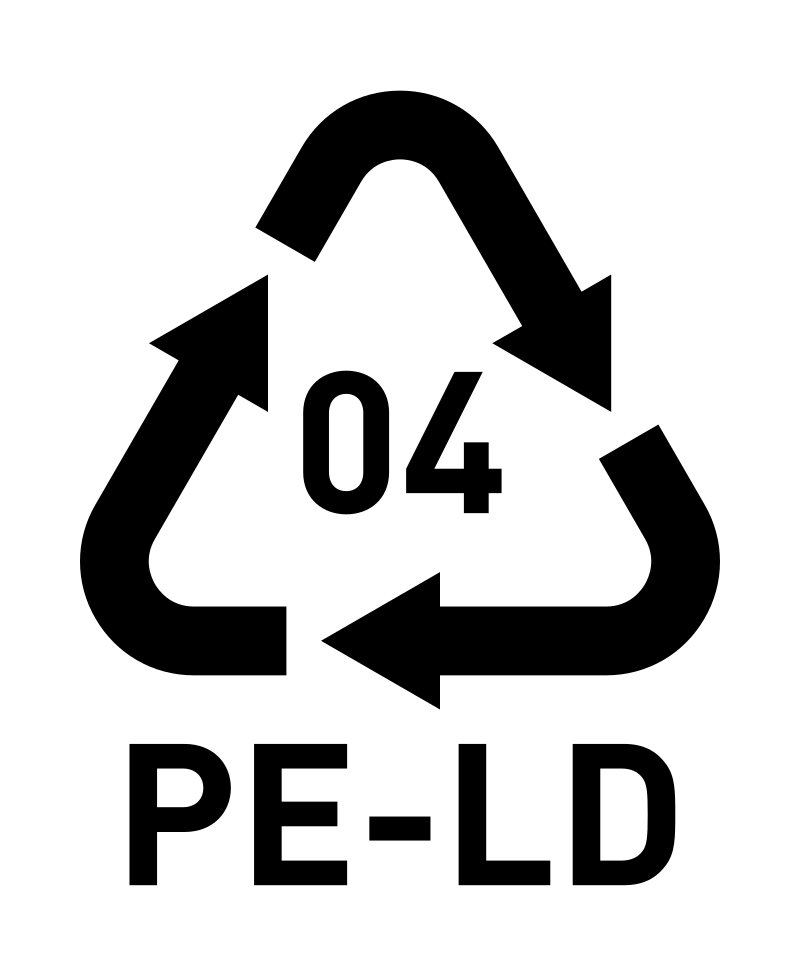

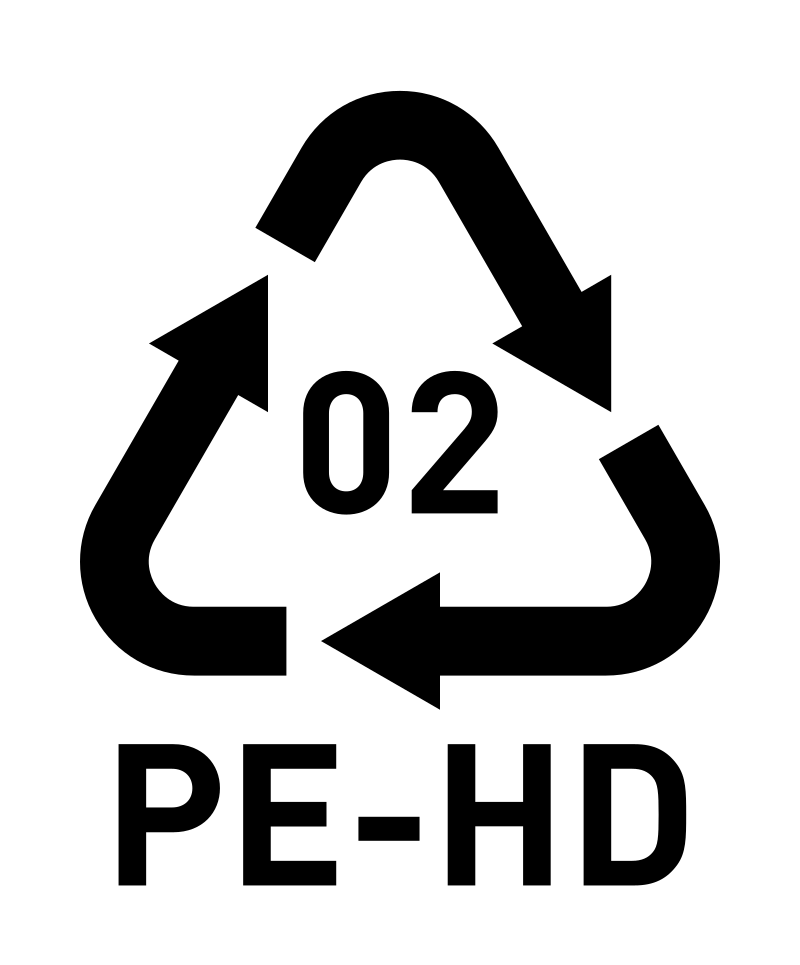

Wet Plastic Film Extrusion Recycling Pelleting Line is mainly used to recycle the waste film of HDPE/LDPE/PP with a degree of dust.

It can decontaminate and exhaust well, to produce high-quality recycled plastic pellets.

Application Recycling material: LDPE/HDPE/PP Wet Plastic Film Waste.

LDPE Wet Plastic Film Extrusion Recycling Extrusion Granulator

| Main Extruder | ||||||||

| Model | SJ-120A | SJ-140A | SJ-140A | SJ-140A | SJ-150A | SJ-160A | SJ-200A | SJ-280A |

| Screw Diameter(mm) | 120 | 140 | 140 | 140 | 150 | 160 | 200 | 280 |

| Screw length(mm) | 2300 | 2300 | 2600 | 3600 | 3000 | 3000 | 3800 | 4300 |

| Material of Screw | 38CrMoAIA, Nitriding treatment | |||||||

| Material of Barrel | 40Cr Nitriding treatment | |||||||

| Degassing | Single Venting degassing | |||||||

| Gearbox | 225-550 | |||||||

| Main Motor(KW) | 30-6 | 37-6 | 45-4 | 55-6 | 75-4 | 75-4 | 75-6 | 90-6 |

| Motor control mode | Soft Control/Frequency Control | |||||||

| Heating zones | 5 | 6 | 7 | 9 | 8 | 8 | 9 | 9 |

| Heating Power(KW) | 28 | 40 | 45 | 65 | 60 | 65 | 75 | 85 |

| Mesh changing mode | 400*400mm hydraulic double screen/ no net die head | |||||||

| Cooling type | Water cooling | |||||||

| Output (kg) | 100-200 | 150-300 | 150-300 | 180-375 | 200-375 | 230-400 | 350-500 | 500-650 |

| Auxiliary Extruder | |||

| Model | SJ-120B | SJ-140B | SJ-125B |

| Screw Diameter(mm) | 120 | 140 | 125 |

| Screw length(mm) | 1500 | 1800 | 1500 |

| Material of Screw | 38CrMoAIA, Nitriding treatment | ||

| Material of Barrel | 40Cr Nitriding treatment | ||

| Degassing | Single Vented Degassing | None | |

| Gearbox | 225-330 | ||

| Main Motor(KW) | 15-4 | 22-4 | Apr-45 |

| Motor control mode | Soft Control/Frequency Control | ||

| Heating zones | 3 | 4 | 5 |

| Heating Power(KW) | 12 | 18 | 25 |

| Mesh changing mode | 400*400mm hydraulic double screen/ no net die head | ||

| Cooling type | Water cooling | ||

Accessories: Conveyor belt, Rake Feeding, Stainless Steel Water Cooling Tank, Air-Dryer, Vibrating Screen, Silo tank, 3.7KW Automatic Feeding Motor, 3.7-4KW Crushing motor, 5.5KW-30 blade Cutting Machine.

Application Recycling material: LDPE/HDPE/PP Wet Plastic Film Waste

PP Edge Trim, PP Biaxial-Orientated Film, Film Extrusion, LDPE Film Roles, Decored, PP Carpets, Post,PP Geotextile, Nonwovens, PE Artificial Gras, HDPE Packging Net,EPS Blocks Foam Extrusion, Bioplastics, PE Compound Bottle Closures, PMMA Injection Molding Sprues, HDPE Automotive Parts Blow Molding etc.

PO Mixed Fraction, Pressed,PE film flakes, PP/PE Mixed Fraction, Mixed packaging films,PP Regrind Fibers, LDPE Flakes, Agricultural Film, HDPE Flakes, LDPE Flakes, PET Fibre, Fibre Spinning, PET Bottle Flakes, PET Skeletons Thermoforming, PET Wovens, PET Nonwovens

We customize the machine and offer the best pricing(FOB, CIF on USD/EUR)as your request and according to your plastic waste sorts, output capacity.

Our payment term is based on T/T, 30% advanced payment by 70% before shipment. It can be negotiated with different situations.

The production time would be controlled within 25 to 30 days. We will keep updated the production status communication with the client.

The equipment set packed by wrap film and loaded by forklift in the container, around one set/20ft container, two sets/40ft container, will be sent by sea.

For each order, we would send our engineer to make the installation and debugging for the machine and provide the operation training service.

We offer one year warranty. For future maintenance, we would provide the related spare parts and build a video conference group to give instructions.

Copyright © 2021 enviromachinery.com. All Rights Reserved. | Privacy Policy